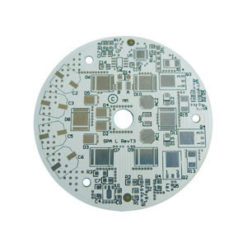

Aluminum PCB

Aluminum PCB The aluminum substrate is a metal-based copper clad laminate with good heat dissipation function. Generally, a single-sided board is composed of a three-layer structure, which is a circuit layer (copper foil), an insulating layer and a metal base layer. For high-end use, there are also double-sided boards designed with circuit layer, insulating layer, aluminum base, insulating layer, and circuit layer. Very few applications are multi-layer boards, which can be made by bonding ordinary multi-layer boards with insulating layers and aluminum bases.

Compared with the traditional FR-4, the aluminum substrate can minimize the thermal resistance, so that the aluminum substrate has excellent thermal conductivity; compared with the thick film ceramic circuit, its mechanical properties are extremely good.

In addition, aluminum substrates have the following unique advantages:

Meet RoHs requirements;

More suitable for SMT process;

In the circuit design scheme, the thermal diffusion is extremely effectively treated, thereby reducing the operating temperature of the module, extending the service life, and improving the power density and reliability;

Reduce the assembly of heat sinks and other hardware (including thermal interface materials), reduce product volume, and reduce hardware and assembly costs; optimize the combination of power circuits and control circuits;

Replace fragile ceramic substrates to obtain better mechanical durability.

Special PCB

Special PCB

Aluminum PCB