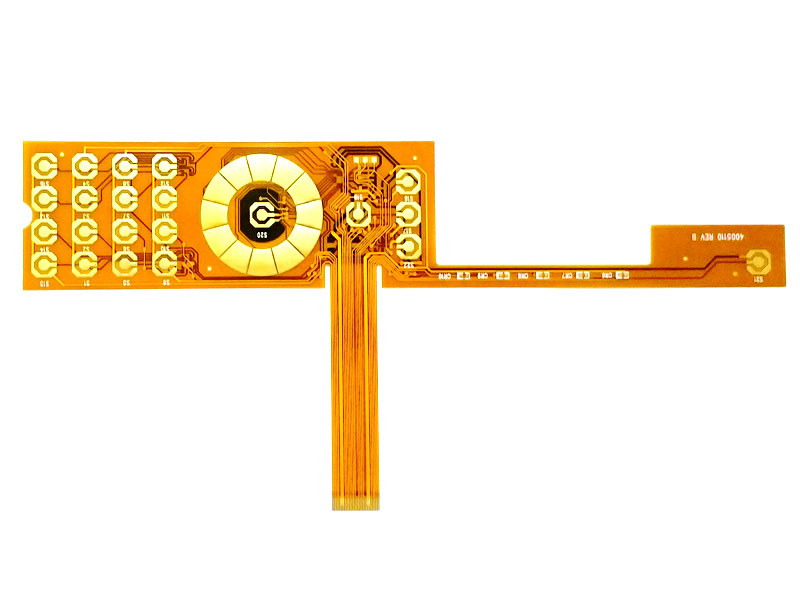

2 layer flex board

Substrate:PI polyimide film 25μm (1mil), 12.5μm (1/2mil)

Copper foil :12μm (1/3oz), 35μm (1oz), 17.5μm (1/2oz)

Cover material:PI polyimide film 25μm (1mil), 12.5μm (1/2mil)

Photosensitive cover coating/photosensitive cover film/and special materials

Surface treatment: tin, gold plating, immersion gold, OSP anti-oxidation, immersion silver